Kneading machine

From manual handling to a faster & more efficient machine.

Client

Pfizer

Duration

1 year

“How can we disassemble vacuum-packed plungers more efficiently?”

Pfizer

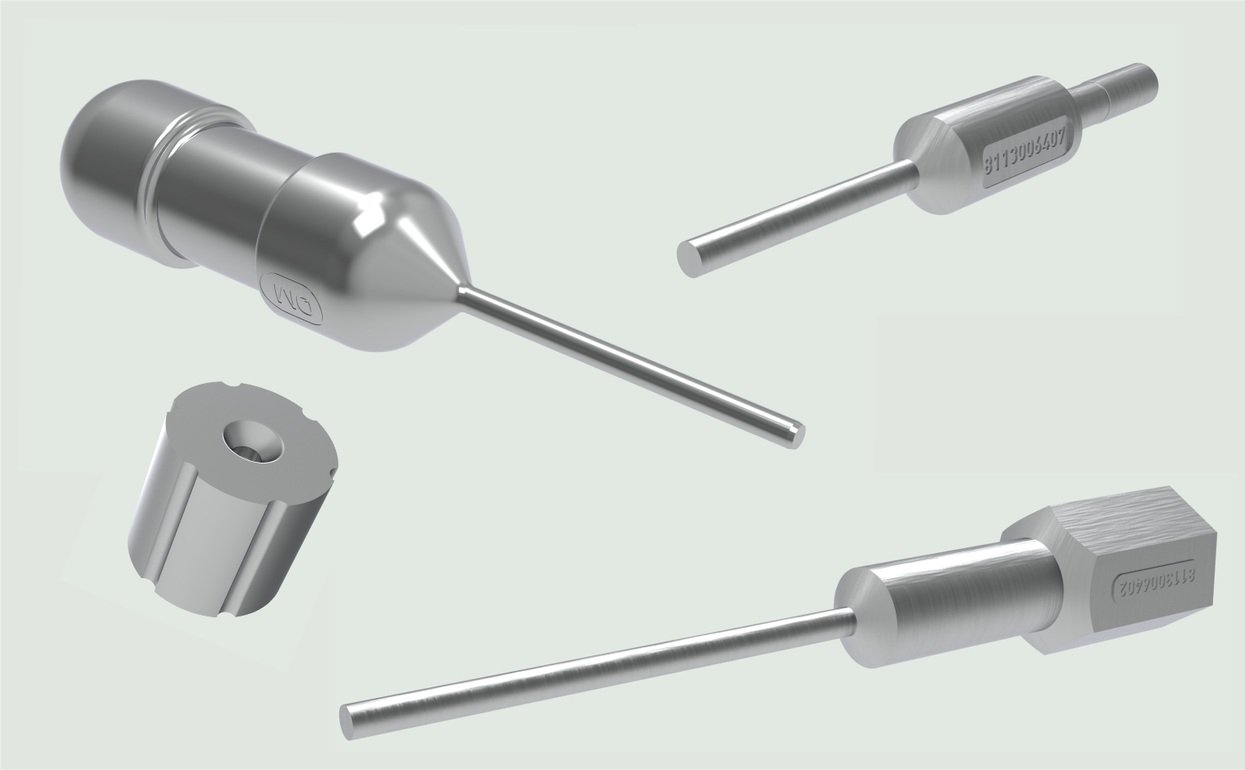

We proudly present the kneading machine project, a solution crafted to address Pfizer's challenge in disassembling plungers’ stoppers made from vacuum-packed elastomers. Faced with the need to disassemble these components efficiently for integration with other parts, Pfizer sought our expertise to automate the process.

— Objectives

AUTOMATED DISASSEMBLY

The primary objective was to devise a solution for the efficient disassembly of plunger’s stoppers made from vacuum-packed elastomers. The manual process was not only time-consuming but also prone to variations, prompting the need for a consistent and automated approach.

— Some key features

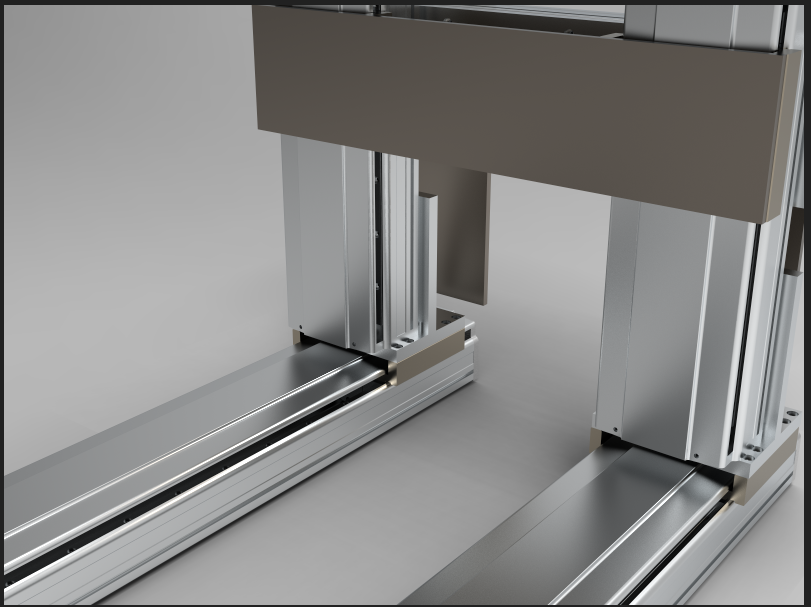

STREAMLINED DISASSEMBLY PROCESS

Our goal was to transition from manual labour to a machine-driven process that not only accelerated the workflow but also ensured uniformity in the disassembly, providing a foundation for improved system efficiency.

CONCEPT TO EXECUTION

Fosfor took the challenge head-on, moving from conceptualization to the implementation of the kneading machine. This innovative solution streamlined the previously manual and time-intensive task of disassembling elastomer-packed plungers’ stoppers.

Witness the evolution from manual intricacies to a seamless and consistent machine-driven solution, epitomizing the fusion of creativity and engineering excellence in the world of design innovation.