We design, engineer & produce the healthcare products of tomorrow.

Since 2006, we are specialized in crafting hardware parts and products that adhere strictly to ISO terms and regulatory standards, ensuring the highest level of quality and safety in healthcare solutions.

— Our mission

At Fosfor Medical, our mission is to develop & deliver high quality medical parts & devices to optimize tasks & streamline processes.

By merging design thinking with clever engineering & manufacturing techniques, we assure competitive advantages in your medical development process.

— What we do?

Concept design & engineering

-

Collaborate with stakeholders to define design goals.

Conduct market research and needs analysis.

Establish user requirements and specifications.

Create initial design concepts and mockups.

-

Evaluate technical viability.

Assess regulatory requirements and constraints.

Identify potential risks and challenges.

Determine feasibility of meeting design goals.

-

Develop detailed design specifications.

3D-CAD and prototyping techniques.

Iteratively refine designs based on feedback.

Conduct usability testing and validation.

-

Perform structural and performance analysis.

Optimize design for efficiency and safety.

Validate design through simulation and testing.

Address identified risks and mitigate hazards.

Manufacturing & logistics

-

Develop manufacturing process workflows.

Determine resource requirements and capacities.

Establish quality control checkpoints.

Optimize efficiency and minimize waste.

-

Identify reliable suppliers and vendors.

Qualify suppliers based on quality standards.

Establish supply chain agreements and contracts.

Monitor supplier performance and compliance.

-

Set up manufacturing facilities and equipment.

Train personnel on production processes.

Plan for scalability and capacity expansion.

Implement lean manufacturing principles.

-

Coordinate shipping and distribution logistics.

Ensure compliance with regulatory requirements.

Implement inventory management systems.

Optimize transportation routes and schedules.

Quality assurance & control

-

Establish a robust Quality Management System.

Define procedures for quality assurance.

Train personnel on quality standards and procedures.

Ensure compliance with ISO and regulatory standards.

-

Inspect raw materials and components upon receipt.

Verify conformance to quality standards.

Reject non-compliant materials or components.

Document and track inspection results.

-

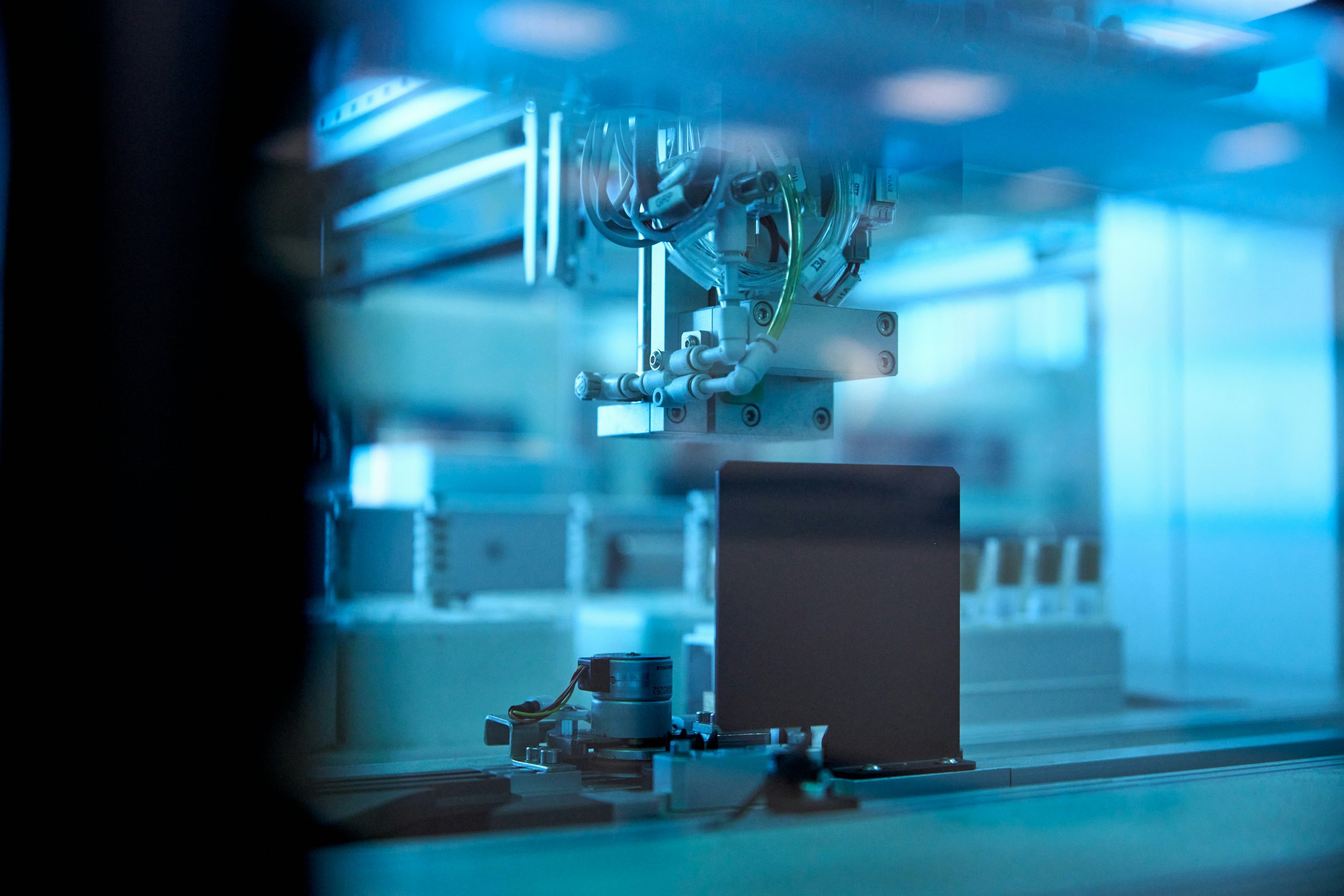

Implement real-time monitoring of production processes.

Conduct inspections at key production stages.

Identify and address deviations from standards.

Ensure consistency and reliability of products.

-

Perform comprehensive inspections of finished products.

Conduct functional testing and performance evaluation.

Verify compliance with design specifications.

Document and report test results for traceability.

— For whom?

Medical and Pharmaceutical Device Companies

We foster strategic partnerships for product development and manufacturing. We offer expertise in engineering and manufacturing to support the creation of innovative medical devices and processes that meet regulatory standards and optimize performance. Whether it's co-developing new products or outsourcing manufacturing processes.

Hospitals & Research Institutions

We translate innovative ideas into practical solutions. Our focus is on custom device development tailored to specific clinical or research needs, ensuring compatibility with existing infrastructure and workflows. Through technology transfer and commercialization support, we help bring research innovations to market.

Accelerating Medical Device Start-ups

At Fosfor Medical we support entrepreneurship in the healthcare industry by providing support throughout the product development process, from rapid prototyping and validation to regulatory compliance and manufacturing. By offering strategic guidance, access to industry networks and mentorship, we empower start-ups to navigate the challenges of bringing a new medical device to market.

— Some succes stories

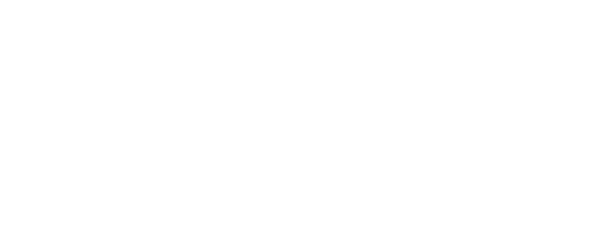

Pharmaceutical device company

Optimizing petri-handler automation control (patented)

Hospital & research institutions

Manufacturing of surgical tools for a veterinarian

Medical start-up

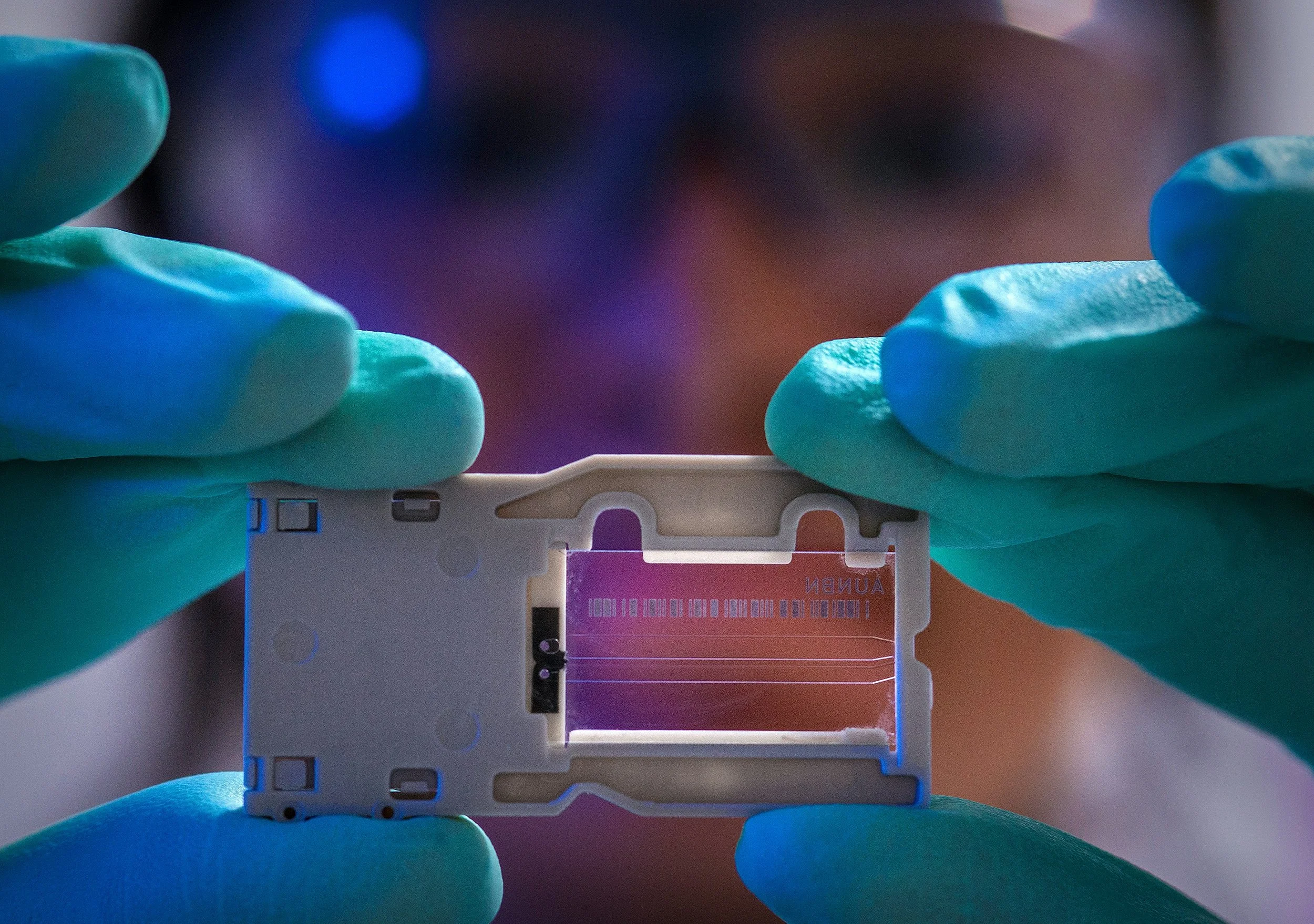

Manufacturing of a urine collector for Novosanis

Medical start-up

Manufacturing of a vaccination tool for IDEVAX

Pharmaceutical device company

Kneading machine to optimize manual manufacturing process for Pfizer

Pharmaceutical device company

Packaging line optimization by producing titanium parts for Pfizer

— Compliance, safety & quality first

-

Our operations are guided by ISO 13485, demonstrating our dedication to meeting the rigorous requirements of the medical device industry.

-

To ensure the integrity of our manufacturing processes, we operate state-of-the-art cleanroom facilities for injection molding and assembly of parts.

-

From incoming material inspections to final product testing, we maintain strict quality control measures to deliver products that meet the highest standards of safety and reliability.

Ready to make your healtcare innovation tangible?

Let’s proceed step by step. Our team is already looking forward hearing from you.